GlassKote Float Glass Industries

Shaping the Future of Glass

“Thanks for the detailed analysis that DataESG have undertaken in assessing the sustainability of this proposed low-iron float glass plant. The assessment showed how we will not only deliver the clearest, strongest, smartest glass ever made; it will drive a new era of sustainable glass manufacturing."

GlassKote Float Glass Industries is a global provider of turnkey solutions for float glass production, serving sectors such as construction, automotive, and renewable energy. Their low iron float glass production processes produce ultra-clear glass with high light transmittance for solar panels, architectural facades, and high-end interiors. With annual production capacity exceeding 500,000 tonnes, and operations spanning multiple regions, GlassKote faces escalating pressures to minimise their environmental footprint while maintaining cost efficiency.

This case study summarises a major environmental assessment conducted by DataESG for GlassKote’s new 650 TPD (Tonnes per day) Low‑Iron Float Glass Plant & 400 TPD Waste‑to‑Energy Facility in Queensland. It outlines a high-level review of the assessment and proposed technologies to reduce GassKote’s emissions of CO₂ (Carbon Dioxide), NOₓ (Nitrogen Oxide) and SOₓ (Sulfur Oxide) discharged in the production of this volume of low iron float glass.

The Challenge

In August 2025, GlassKote engaged DataESG to evaluate the sustainability of their proposed new 650 TPD Low‑Iron Float Glass Plant & 400 TPD Waste‑to‑Energy Facility in Queensland, amid rising regulatory and stakeholder demands. Key challenges included:

- High Resource Intensity: Float glass production is energy-intensive, with significant natural gas and electricity usage contributing to high Scope 1 and 2 emissions.

- Environmental Impacts: Water consumption, waste generation, and raw material sourcing posed risks, particularly in silica and soda ash supply chains.

- Regulatory Pressures: Compliance with Australia’s Mandatory Climate Related Disclosures and international ESG reporting requirements was critical to avoid trade barriers.

GlassKote required a detailed assessment to benchmark performance, identify risks, and develop a roadmap for net-zero ambitions.

The Solution

DataESG assessed three scenarios utilising advanced data tools and industry-specific benchmarks for the glass manufacturing sector as follows:

- Stage 1 BAU (Business as Usual): Conventional gas-fired furnace, standard cullet ratio (~15%), no advanced abatement technologies.

- Stage 2 ESG Integration: Incorporates regenerative and oxy-fuel burners, low-NOₓ technology, flue gas recirculation, Selective Catalytic Reduction (SCR), and initial carbon capture deployment (~50% capture efficiency).

- Stage 3 Full Sustainability Model: Maximised cullet use (≥45%), 95% carbon capture (K2-CO₂ or equivalent), renewable electricity supply for auxiliaries, best-practice NOₓ/SOₓ controls, and closed-loop water systems. Stage 3 requires the integration of advanced oxy-fuel combustion, CCUS (carbon capture, utilisation, and storage), and high cullet use. The target is ≥45% cullet input for standard float glass; however, due to low-iron glass purity requirements, the cullet ratio is adjusted to 30–35% to maintain optical clarity and meet premium architectural specifications.

Stage 3 represents the optimised operational phase of the Queensland low-iron float glass plant, in which all planned sustainability measures are fully deployed and integrated into operations. This stage delivers the largest emissions reduction and the strongest environmental credentials, ensuring compliance with international best practice and maximising investor confidence.

Emissions Factor Source: All emissions intensity calculations in the assessment used the Australian National Greenhouse Accounts (NGA) Factors 2023 for stationary energy combustion of natural gas in manufacturing. The 2023 factor was selected as it reflects the most current, government-published dataset and ensures alignment with Australian regulatory reporting requirements, including NGER (National Greenhouse and Energy Reporting) compliance.

Results and Impact

- Direct CO₂ Reduction: ~30% lower than Stage 1 (Business-as-Usual) operations.

- Annual Emissions: Reducing from ~154,000 tCO₂/year (BAU) to ~23,550 t/year, an annual saving of ~130,850 tCO₂ (85% reduction).

- Cumulative Benefit: Over 10 years, ~828,000 tCO₂ avoided compared to the business-as-usual baseline, based on an emissions intensity of 0.300 tCO₂/t (Stage 2 mid-case scenario).

The DataESG analysis found that the cumulative effect of the above reductions over a 10-year period is even greater and represents the potential for an 828,000 reduction in CO₂.

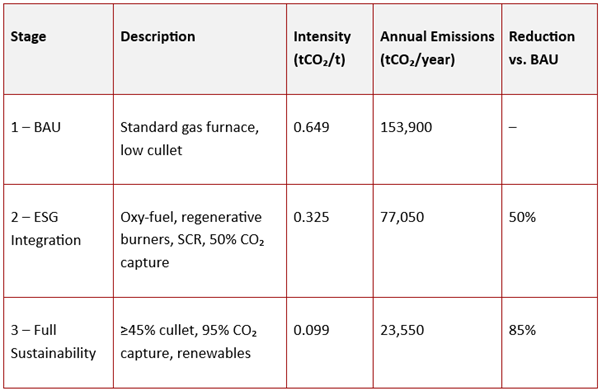

The forecast scenarios and emissions reductions modelled in this assessment require the full implementation of Stage 3 technologies and actions. Table 2 outlines each of these stages to show the intensity of CO₂/ per tonne (CO₂/t), annual emissions per year, and potential emissions reductions against the BAU baseline.

Quantifiable metrics from the assessment:

Table 2. Staged ESG integration, intensity, annual emissions and reduction against BAU baseline.

As can be observed in the table above, incorporating a full integration of ≥45% cullet, 95% CO₂ capture, and renewables Stage 3 represents a potential for an 85% reduction against the BAU baseline.

Conclusion

DataESG’s sustainability assessment for GlassKote’s low iron float glass plant demonstrated the transformative power of sustainability in resource-intensive industries. By utilising the proposed technologies outlined in this case study, DataESG were able to assess and quantify how GlassKote can implement an innovative 3-stage sustainability strategy for its Queensland plant to mitigate emissions from a manufacturing process that has historically been high in emissions. With Stage 3 fully implemented, the plant will achieve 828,000 tCO₂ avoided over 10 years, aligning with investor priorities for climate-positive infrastructure.

By delivering data-backed insights and practical strategies, DataESG enabled GlassKote to understand and reduce its environmental impacts, improve social responsibility, and strengthen governance. This partnership will not only enhance operational resilience but also position GlassKote as a frontrunner in sustainable glass manufacturing, proving that environmental stewardship can drive business success.

ESG Consulting

Expert ESG consulting to align with Australia's regulatory requirements and sustainability goals. Tailored advice to navigate complexities and drive positive impact.

ESG Strategy Development

Strategic ESG planning to meet business objectives, national and global standards. Create resilient, future-proof strategies that support long-term success.

ESG Data Management & Software Solutions

Efficient ESG data solutions to streamline compliance and performance tracking. Harness the power of data to enhance reporting and sustainability outcomes.

ESG Reporting & Disclosure

Transparent ESG reporting solutions that meet regulatory standards and build stakeholder trust. Simplify compliance and enhance accountability with our expert support.

Contact Us

HEAD OFFICE

Ground Floor, 1 Albert Rd,

MELBOURNE, VIC, 3000

AUSTRALIA

1300 873 112

info@dataesg.com.au